Multi Tier Racking in Dubai, UAE

Multi-Tier Racking Solutions by Vertical Heights Global are designed to maximize your warehouse space efficiently across Dubai and the United Arab Emirates. These innovative systems offer multiple storage levels, enhancing organization and increasing capacity. Ideal for various industries, multi-tier racking solutions improve accessibility and productivity while optimizing vertical space. With custom configurations and expert installation, we ensure your warehouse operates at peak efficiency.

Multi Tier Racking in Dubai, United Arab Emirates

For businesses operating in Dubai and across the United Arab Emirates, multi-tier racking is an increasingly popular solution due to its ability to maximize storage in a cost-effective manner. With space at a premium in major cities like Dubai, Abu Dhabi more businesses are opting for vertical storage solutions. Our multi-tier racking solutions are tailored to meet the unique requirements of each business, ensuring optimal storage and operational efficiency.

At Vertical Heights Global, we are proud to be a trusted multi-tier racking supplier in Dubai, United Arab Emirates. Our team of experts works closely with clients to design, manufacture, and install systems that address their specific storage needs. Whether you require a compact multi-tier system for a small warehouse or a large-scale solution for an extensive storage facility, we have the experience and resources to deliver.

What is Multi-Tier Racking?

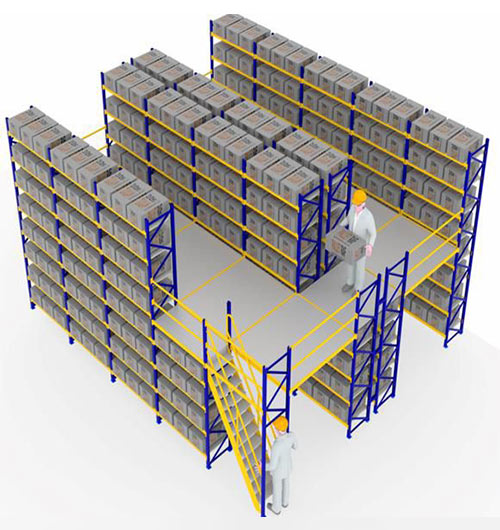

Multi-tier racking is an advanced storage system that maximizes vertical space by creating multiple levels of shelving or racking within a warehouse. This system is particularly beneficial in environments where floor space is limited but height is available. Multi-tier racking allows for the creation of multiple storage levels, ensuring you can store more products without requiring additional square footage.

Features of Multi-Tier Racking

Multi-tier racking systems are highly flexible and can be designed to meet specific storage needs. Some of the key features of multi-tier racking include:

- Maximized Vertical Space: By utilizing the available vertical height of your warehouse, this system ensures you make the most out of your existing space without expanding your warehouse area.

- Customizable Layout: These racking systems are highly customizable, allowing you to design a layout that perfectly fits your storage requirements, be it for bulk items or smaller, more delicate goods.

- Easy Access: Multi-tier racking provides quick and easy access to stored products, ensuring smooth warehouse operations.

- Cost-Efficient: By optimizing the use of space, you can save on real estate costs while maintaining high efficiency and storage capacity.

Benefits of Multi-Tier Racking Solutions

The multi-tier racking system is a cost-effective solution that offers a range of benefits to businesses. Let’s dive into some of the significant advantages:

- Increased Storage Capacity: By adding multiple layers of racks, multi-tier racking significantly increases the storage capacity of a warehouse. This is especially useful in smaller facilities where ground space is scarce, but vertical space is abundant. For companies dealing with a high volume of inventory, this system provides an ideal solution.

- Better Organization: Multi-tier racking solutions in Dubai, United Arab Emirates allow for more organized storage by separating products into different categories on each level. This structured approach not only simplifies inventory management but also helps improve productivity, as workers can easily locate and retrieve items.

- Enhanced Safety: Safety is paramount in any warehouse, and multi-tier racking systems are designed with this in mind. These systems include railings, handrails, and safe access points like staircase and walkways aisles using various type of steel grating options in galvanized steel, cargo lifts, loading gates, gravity slopes for carton boxes, anti-collapse mesh cladding ensuring that employees can work efficiently without risk of injury. Additionally, load-bearing capacities are carefully calculated to prevent overloading and potential hazards.

- Cost-Effective Storage Expansion: Instead of investing in costly warehouse expansions or new facilities, businesses can opt for multi-tier racking to meet growing storage demands within their existing warehouse. This system reduces the need for additional warehouse space investment, making it a more economical choice for businesses looking to scale up their operations and storage requirement.

Call Vertical Heights Global To Help You Make The Right Choice For Your Inventory And Operational Needs

Industries Benefiting from Multi-Tier Racking

Multi-tier racking solutions are versatile and can be applied in various industries. Some of the industries that benefit the most from this type of storage system include:

- Retail: Large-scale retail outlets and distribution centers benefit from multi-tier systems for storing various products, ensuring quick access for order fulfillment.

- E-commerce: The fast-paced nature of e-commerce requires efficient storage solutions to meet order demand. Multi-tier racking helps e-commerce businesses manage their inventories more effectively.

- Automotive: Automotive spare parts and accessories can be easily stored and accessed using multi-tier racking systems, helping companies manage large inventories with ease.

- Pharmaceuticals: With a need for highly organized and accessible storage, multi-tier systems are ideal for the pharmaceutical industry.

- Logistics: In the logistics industry, multi-tier racking systems are essential for optimizing warehouse space, improving operational efficiency, and facilitating easy movement of goods for faster order processing.

Integrating Multi Tier Racking with Other Storage Solutions

When it comes to maximizing the efficiency of a warehouse, it’s not just about adding more racks. A comprehensive storage solution also includes complementary systems like storage racking, shelving Cabinets and lockers, which help to create an organized and secure environment. At Vertical Heights Global, we help businesses integrate multi-tier racking with other systems, ensuring that all available space is utilized to its full potential.

Installation of Multi-Tier Racking Systems

1. Pre-Installation Planning and Site Assessment

Before installation begins, thorough planning is crucial. This includes:

- Site Assessment: Evaluate the space where the racking system will be installed. Consider the height of the warehouse, the layout of existing structures, and potential obstructions like pillars or lighting fixtures.

- Load Calculation: Determine the weight capacity of the system based on the types of goods you’ll store. Ensure that the racking is designed to support the load to prevent structural damage and ensure safety.

- Safety Considerations: Plan for safety features such as railings, safety barriers, and fire exit points. Also, consider the type of access needed, such as staircases or cargo lifts, load gates, gravity slopes.

2. Design Customization

One of the key advantages of multi-tier racking is its flexibility. The racking system can be customized to suit your specific needs:

- Rack Height and Levels: Depending on your space and product requirements, determine the number of tiers needed. The racking height should allow for easy access to goods without compromising safety.

- Aisle Space: Plan the width of aisles between racks to allow for smooth material flow, whether by personnel or material handling equipment like platform trolley, order picking carts, roll cage trolleys, shelving trolleys.

- Material Choice: Select high-quality materials, such as durable steel, to ensure the racking system’s stability and longevity.

3. Installation Process

Once the planning and design are complete, the actual installation begins. This involves:

- Assembling the Framework: The basic structure of the multi-tier racking is assembled first. This includes the vertical supports, horizontal beams, and any required cross-bracing for stability.

- Installing Shelving and Platforms: Shelves and platforms are installed on the racking system to create the different storage levels. Depending on the system, these are made from mild steel,galvanized steel drop over panels, galvanized wire meshdecking panels, or plywood.

- Ensuring Stability: It’s crucial that the entire system is anchored securely to the floor and, if necessary, to the walls. This prevents tipping or collapsing under heavy loads.

- Adding Safety Features: Railings, barriers, back and side cladding sheets either using wire mesh or solid steel panels and signage should be installed to ensure safe use of the racking system. Adequate lighting should also be considered to improve visibility, especially in multi-level systems.

4. Inspection and Testing

Before the racking system is put into use, a thorough inspection should be conducted to ensure that:

- The structure is stable and secure.

- The load capacity is adhered to.

- Safety measures are in place, such as railings and signage.

- Any required certifications or regulatory standards are met.

Testing the system with a controlled load can also help verify its strength and stability before full-scale operations commence.

Maintenance of Multi-Tier Racking Systems

1. Regular Inspections

Routine inspections should be conducted to identify any signs of wear, damage, or potential safety hazards. Important areas to inspect include:- Structural Integrity: Check for any signs of rust, bent beams, or damaged shelves. These can compromise the system’s strength and load capacity.

- Safety Equipment: Ensure all safety barriers, railings, and signage are intact and functioning as intended.

- Anchors and Fixings: Inspect the anchors and fixings that secure the racking to the floor and walls. Any looseness or wear should be addressed immediately to prevent accidents.

2. Load Management

Overloading is a frequent cause of racking system failure. Ensure that all workers and employees are aware of the system’s load capacity and that it is not exceeded at any point. Conduct regular checks to verify that loads are distributed evenly across the tiers and that heavy items are stored on the lower levels to maintain balance and prevent tripping.3. Cleaning and Environmental Control

Dirt, dust, and moisture can damage the materials and compromise the racking system over time. To mitigate this:- Regular Cleaning: Keep the racking system free of dust and debris by conducting regular cleanings. This also makes inspections easier by removing dirt that could conceal damage.

- Environmental Control: If your warehouse is prone to high humidity or temperature fluctuations, consider using corrosion-resistant materials or applying protective coatings to the racking.

4. Staff Training and Awareness

Employees play a significant role in maintaining the racking system. By providing proper training on how to safely load, unload, and access products stored in the system, you can reduce the risk of damage and accidents.- Safe Loading Practices: Train employees to load goods evenly and within the system’s load capacity.

- Proper Use of Equipment: Ensure that any material handling equipment used, such as forklifts, is operated by trained personnel who understand how to work safely around the racking system.

- Emergency Procedures: Employees should be aware of the safety protocols in case of an emergency, including knowing the location of exits and fire safety equipment.

5. Repairs and Replacements

Any damage to the racking system should be addressed immediately. Even small issues, such as bent beams or loose fittings, can lead to significant problems if left unattended. Regularly replacing worn-out components ensures the system remains in top condition. Additionally, it’s important to work with certified professionals for any major repairs to ensure they are done according to safety standards.Why Choose Vertical Heights Global for Multi-Tier Racking Solutions?

At Vertical Heights Global, we specialize in providing customized multi-tier racking solutions in Dubai And in the entire United Arab Emirates. That meet the unique requirements of businesses across the UAE. Our dedication to excellence, safety, and customer satisfaction distinguishes us from other suppliers. Here’s why businesses prefer our services:

- Tailored Solutions: We work closely with you to design a solution that fits your specific storage needs.

- Expert Installation: Our team ensures that your racking system is installed safely and efficiently, minimizing downtime.

- Quality Products: We use only high-quality materials to ensure the durability and longevity of your storage system.

- After-Sales Support: Our relationship with our clients doesn’t end with installation. We provide ongoing support and maintenance to ensure your system continues to perform optimally.

At Vertical Heights Global, we offer tailored installation services and provide ongoing support to ensure that your multi-tier racking solution performs optimally for years to come. you can increase storage capacity, enhance productivity, and improve the overall organization of your warehouse.Contact us today to get started and transform your warehouse with innovative storage solutions!

FSC India

FSC India